-

-

GIFT City, Gandhinagar, Gujarat - India

Processing

Providing a wide range of metal processing

The metal industry in India is experiencing rapid growth in both production and consumption. The National Steel Policy 2017 aims to triple the current production capacity to 300 MTPA by attracting investments in manufacturing capabilities. Additionally, the policy aims to increase per capita consumption to 160 kgs by 2030, up from the current level of around 60 kgs (Source: www.steel.gov.in).

Furthermore, there is a growing demand for just-in-time processed metals in various industries, driven by a shortage of skilled manpower and investments to meet global quality standards. The existing in-house and standalone metal processing capacities are insufficient to meet the expected growth in supply and demand.

At MetalXperts, we have taken the initiative to provide cutting-edge material processing across India. This endeavour aligns with our mission and vision of becoming our valued clients' preferred and comprehensive sourcing partner.

Metal Processing

Cut-to-Length (CTL)

The metal cut-to-length (CTL) is a process commonly employed in steel industries to produce metal sheets or strips of specific dimensions. It involves cutting large coils or sheets of metal into smaller, predetermined lengths according to the requirements of the customer or the intended application.

Cut-to-Size (CTS)

The metal cut-to-size (CTS) is a common practice in steel industries and other metalworking sectors. It refers to the process of cutting metal coils, sheets, plates, or bars into specific dimensions and shapes as per the requirements of a particular project or customer.

Slitting

Slitting is a process commonly used in the steel industry to cut large coils of steel into narrower strips. The objective of metal slitting is to create narrower and more manageable coils or strips that can be further processed or used in various applications.

Bending

The bending in steel industries refers to the process of manipulating steel or other metal materials to achieve desired shapes or forms. It involves the application of force to deform the metal and create bends, curves, angles, or other geometric configurations.

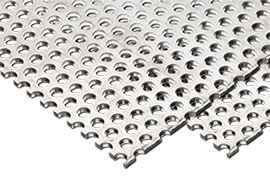

Perforating

The perforating in the steel industry refers to the process of creating a pattern of holes or openings in a metal sheet or plate. Perforated metal has a wide range of applications in various industries, including construction, automotive, aerospace, and industrial manufacturing.

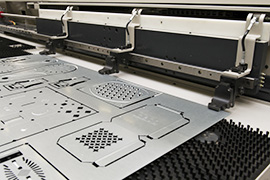

CNC & Laser Cutting

The CNC and laser cutting, both play crucial roles in the steel industry, enabling efficient and precise manufacturing processes for a wide range of products, including automotive components, structural parts, machinery parts, and decorative items.

Bespoke Engineering Solutions

Bespoke engineering solutions in the steel industry refer to custom-designed and tailored engineering solutions that are specifically created to meet the unique requirements and challenges of steel-related projects. These solutions are typically developed by specialized engineering firms or consultants who have extensive knowledge and expertise in the steel industry.

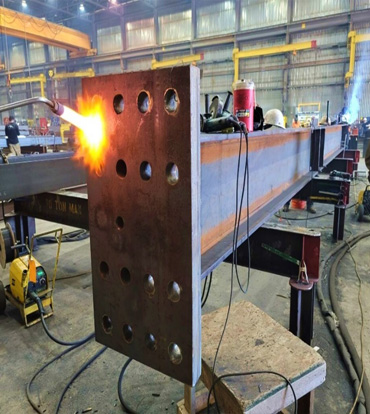

Heavy Fabrication

Railways

Pre Engineered Building

Boilers & Pressure Vessels

Defence

Bridge Girders

Vendor Registration

The purpose of vendor registration is to streamline the procurement process and ensure transparency, efficiency, and accountability.

It helps prevent fraudulent activities, promotes healthy competition, and enhances the overall quality of goods and services procured by an organization.